Matcha Production Process

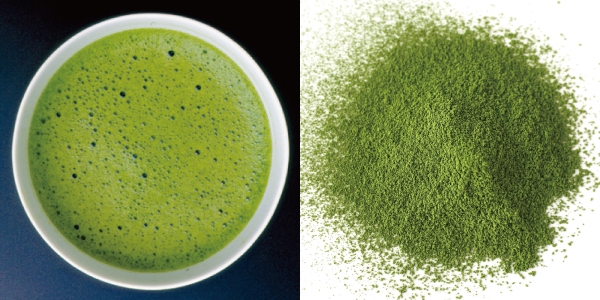

Matcha particles of several microns

are produced slowly with great care and time.

Matcha particles of several microns

are produced slowly with great care and time.

It has a slightly sweet, unique matcha aroma called “Oika” and beautiful green tea leaves.

At AIYA Co., Ltd., we turn carefully grown tea leaves into matcha using the traditional milling method that has been handed down over the years.

The tea mills used to create the fine particles are made by artisans using a technique called “Metate”, which has been passed down from master to apprentice.

Matcha manufacturing process made using Aiya Co., Ltd.'s “traditional tea mortar manufacturing method”

In the beginning of April, when the tea buds grow. Tea fields are covered with black sheets to block out the sunlight. Shielding sunlight inhibits theanine, the flavor component, from changing to tannin, an acerbity component. It also generates the sweet flavor unique to matcha, called “Oika”, and the vivid green color. Tea leaf harvest begins from the 88th day from the beginning of spring (Hachiju-hachiya).

Picked tea buds are delivered to aracha processing factory. High-temperature steaming stunts the fermentation enzyme activities and retains the vivid green color of tea. Then, tea leaves are dried by removing the water content slowly in a large drier. The leaves in this condition are called aracha or tencha aracha.

Stems and veins are removed from aracha and only the leaf part full of nourishment and palatability are left as ingredients. Specifically, aracha is refined in a process of size- sorting, air sorting, re-drying, electrical sorting, and color sorting.

Refined tencha is delivered to the matcha factory. Micron-sized matcha is produced using tea grinders in a manufacturing room under constant temperature and humidity 24 hours a day. High-class matcha for tea ceremony is ground very carefully so one tea grinder can only produce 40 grams per hour.

Ground matcha is packed after final inspection. Only products that pass the final inspection are kept fresh and delivered across Japan and worldwide.

To grind tea with tea grinder is a necessary process to make high-quality matcha. One tea grinder can produce 40 grams of micron-sized high-class matcha for tea ceremony. “Grind setting craftsmen” with skills passed down for generations control the tea grinders which produce such invaluable micro grains. AIYA has traditional craftsmen to hone the techniques to produce top-quality micro grains every day.

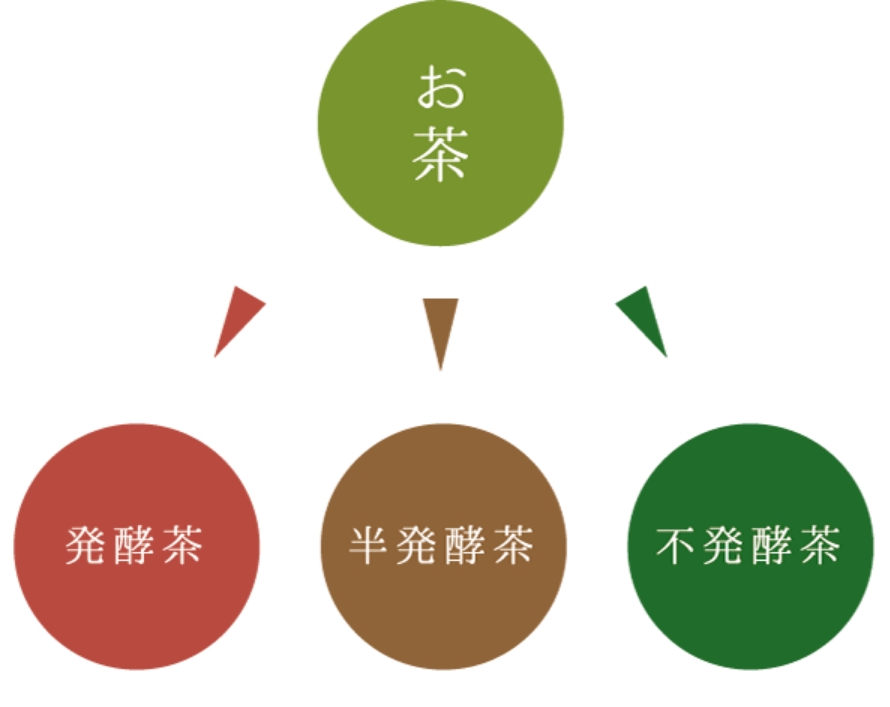

From one tea tree to various teas

Green tea is a representative of “non-fermented tea” which is made by inhibiting the fermentation process through steaming and pan-frying.

Oolong tea is a representative of semi-fermented tea.

Black tea is a representative of fully-fermented tea.

In addition to Matcha, AIYA produces a variety of premium Japanese green teas using techniques that have been inspired by its history and tradition since 1888.

All products have vivid colors deriving from greenness of tea leaves. Various teas with tender colors that can be enjoyed with the eyes, tasted with the tongue and felt within the body.

Tencha is made by steaming the coated tea leaves before harvesting, drying them and refining them, then grinding them in a tea mortar into a powder. It is a superfood that allows you to fully absorb the rich nutrients of tea leaves.

The best-grade tea with smooth aroma and mild sweetness. Flavorful taste can be brought out by long extraction with lukewarm water.

A balanced daily tea that has all umami, sweetness, astringency and aroma of green tea. Both refreshing aroma and mild sweetness are contained.

This is roasted bancha. Leaf color is brown. Recommended for children and sick persons because of its low bitterness and sourness and light taste.

A blend of sencha and brown rice (domestically-produced glutinous rice). Aromatic and rich flavor. Genmaicha instantly brewed with boiling water has a nice smell and rich flavor.

Stem sorted in the process of producing matcha and gyokuro. This tea has a sweetness similar to gyokuro and a unique stem flavor. It can be brewed easily with hot water.

PageTop

PageTop